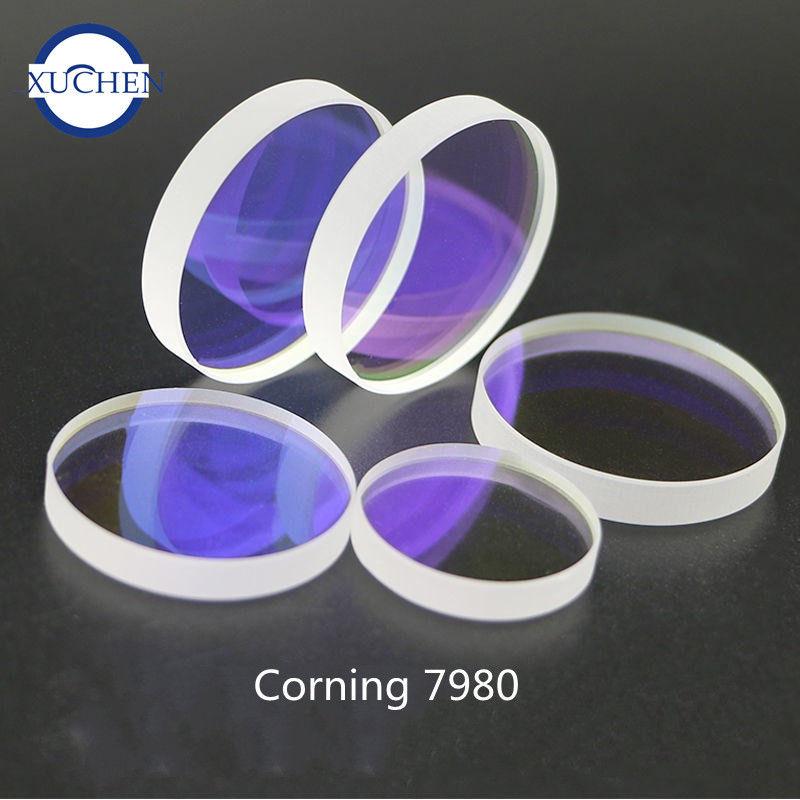

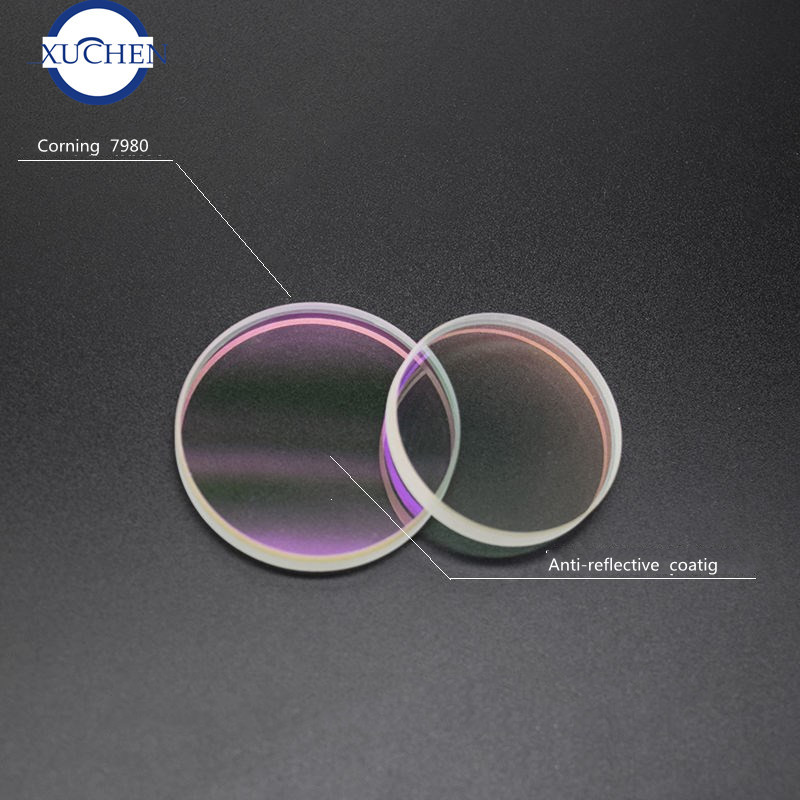

113*3mm Corning 7980 Material 1064nmAR for laser machine 8000W-15000W

Introduction of the Corning 7980

Corning 7980 produced by Corning company of the United States is a kind of high-purity fused silica glass, which has excellent optical properties, low refractive index change, low expansion coefficient, low birefringence value, and good light transmittance from ultraviolet band to infrared band.

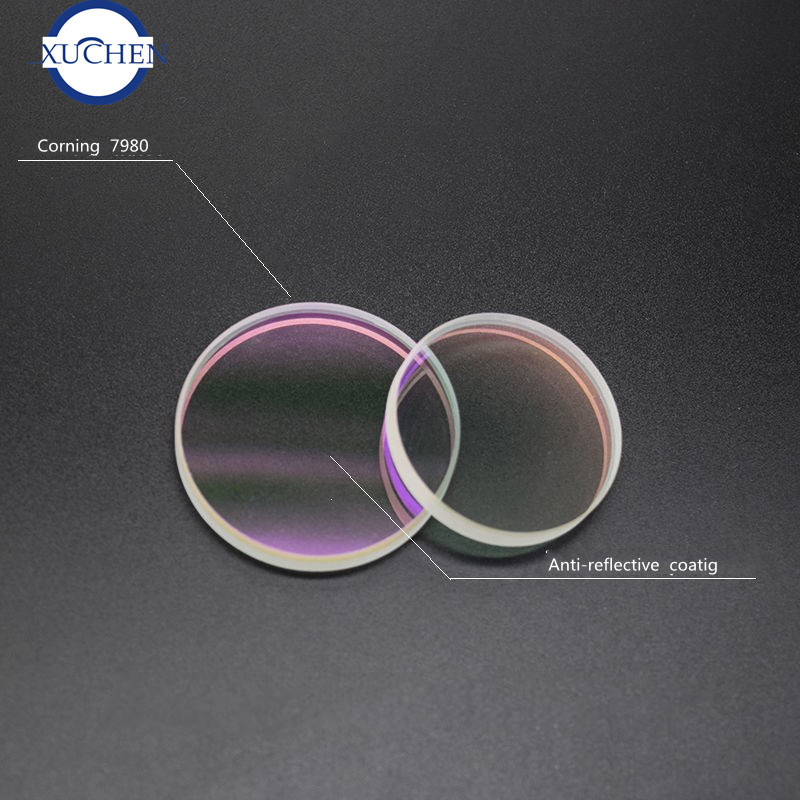

Substrate:Corning 7980 Fused silica glass.

Transimittance:Tave=99%

Size specification: Support customization

Surface quality :60-40, 40-20

Chamfer : 0.02mm*45 degree

Process: Cutting -Chamfer- Polishing -Coating.

Coating : 1064nmAR,532nmAR,650nmAR,915nmAR, (Anti-reflective Coating).

Characteristic of Coring 7980

1. Reflective and catadioptric systems are mostly used. The light transmission characteristics and mechanical properties of optical glass limit the application of lens system in infrared optical system.

2. The performance evaluation is based on the sensitivity and signal-to-noise ratio matched with the detector. The infrared system is an optoelectronic system. The receiver L is an optoelectronic device. The resolution is limited by the size of the optoelectronic device. The requirements for the optical system are reduced.

3. The field of view is small, the aperture is large, the receiving area of the detector is small, the reflection system has no color difference, and the quality requirements of the system object are not high.

4. Scanner is used. When the detector array is a linear array, Corning 7980 often uses a scanner in order to realize the scanning and imaging of space targets.

5. The particularity of wavelength makes the system heavy and expensive. The wavelength of common infrared band is about 5 ~ 20 times that of visible light. In order to obtain a high-resolution system, there must be a large aperture.

What is the polishing process of optical lens?

Optical lens is the lens made of optical glass, which generally refers to the lens that can transmit and adjust visible light. The optical lens must be measured by optical instruments to check whether the purity, transparency, uniformity, refractive index and dispersion index meet the specifications. The qualified glass block is heated and forged to form the optical lens rough embryo. After the optical lens is finely ground with grinding fluid, there is still a thick crack layer on the surface. The method to polish the crack layer is polishing. Optical glass lens molding technology is a * * optical element processing technology. It puts the softened optical glass into the * * mold and directly molds the optical parts that meet the use requirements at one time under the conditions of heating, pressurization and no oxygen.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!