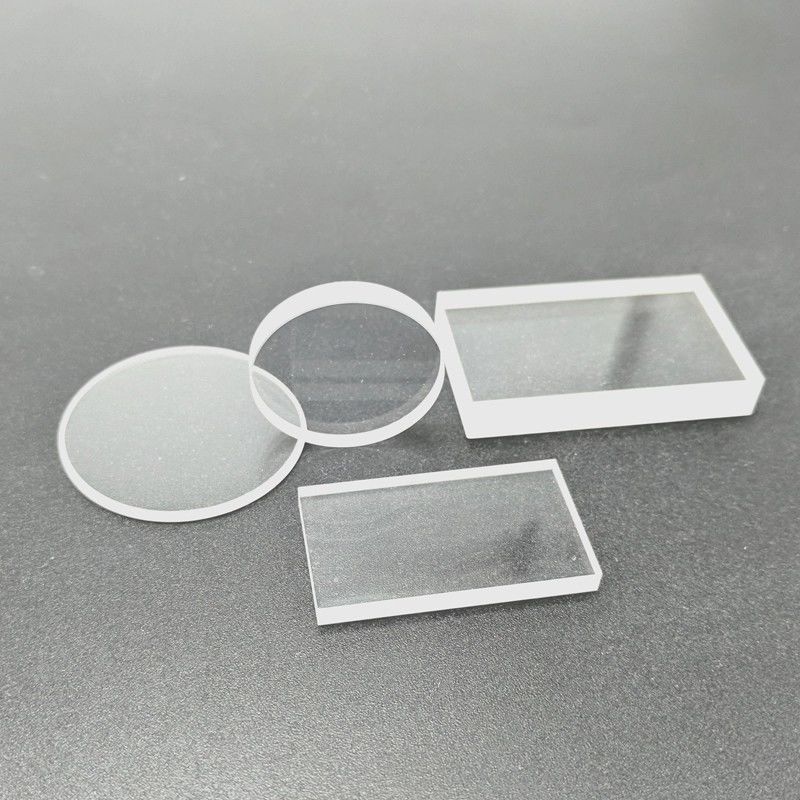

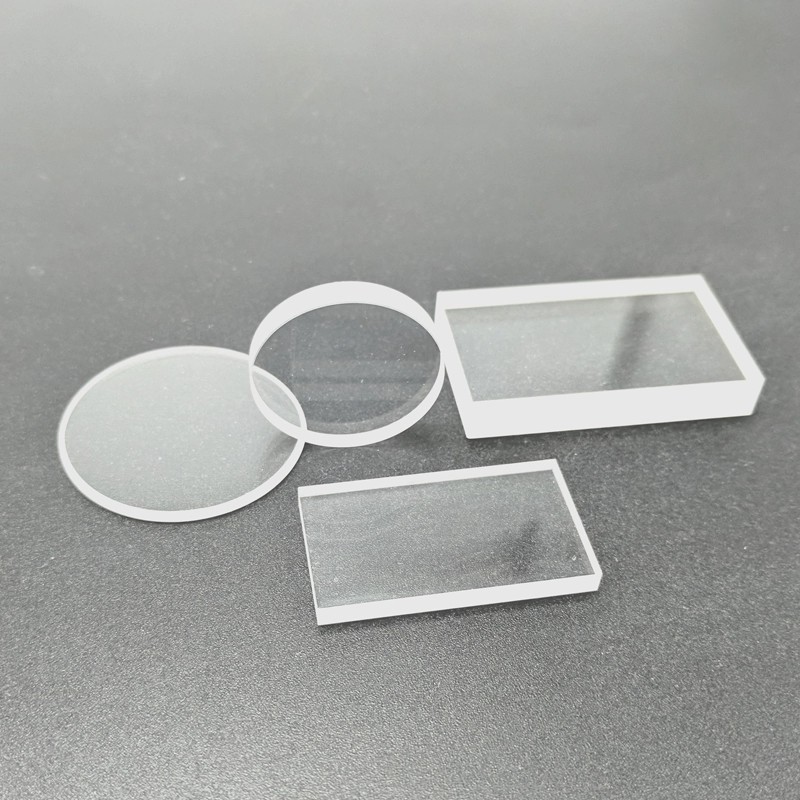

650 & 900&1000nmAR 89*72*5mm Laser Optical Lens JGS1 laser machine

Laser protective lens

Laser Optical Lens base material is quartz material, which is transparent. Laser Optical Lens is finely processed by grinding, polishing, coating and other processes. From the side, Laser Optical Lens it shows light color. Laser Optical Lens is mainly used in laser cutting to prevent splashing of sundries and avoid splashing to damage the lens. Laser Optical Lens is widely used in laser welding machine, laser cutting machine, laser marking machine and so on. For the needs of various styles, we will do it.

It is made of imported crystal material through precise cutting, grinding, polishing, coating and other processes. Double-sided coating 1064nmAR anti-reflection coating.

parameter of Laser Optical Lens

| dimension |

89*72*5mm |

| Coating |

650&900&1000nmAR(Double coated) |

| Dia tolearance |

-0.1mm |

| Thickness tolearance |

±0.1mm |

| Chamfer |

45 degree*0.2mm |

| claim |

laser welding/cutting/marking machine |

| Material |

Imported Quartz JGS1 |

| virtue |

1. Top quality glass with CE certificate,exporting to more 60 countries in the world |

| 2. Unique designed strong wooden case, solving the problem of breakage |

| 3. Professional sales team, offering personalized and dedicated services. |

| 4. 24-hours online, we could discuss the item whenever and wherever. |

Fearture of Laser Optical Lens

1. Hard 4-5 times higher than ordinary float glass, with more than thermal cracking annealed or heat strengthened glass.

2. Once the rupture, the glass will break down into small cubes debris harmful to humans.

3. unique design, quality assurance and competitive price.

4 can be customized according to needs.

5. diverse styles.

Specification of Laser Optical Lens

1. high transmittance, cutting speed

Light transmission rate of up to 99.5%, which can effectively improve the cutting speed. Anti-reflection film having a high damage threshold is coated on both sides of the lens, and effectively reduces the loss due to reflection.

2. The double-sided coating, durability

Long life, more durable double-layer coating can effectively protect the lens from spatter and other hazards, thereby increasing the life of the lens

3. Excellent optical properties and good stability

Excellent thermal stability, excellent laser resistance

4. facilitate the use and not to hurt the hand

45 degrees Protection humane whole point of design, safety and ease of use, not to hurt the hand

Function:

The main function of laser protective lenses is to prevent dust and splashes from damaging the focusing lens. However, the prices of protective lenses on the market vary greatly, ranging from tens of yuan to hundreds of yuan, and the price varies greatly, and the quality is also different. Of course, shoddy is not uncommon. If the lens is not selected properly, it will cause large laser loss, frequent damage to the protective lens, unstable product quality, and cause serious losses to the enterprise. Therefore, choosing the right protective lens is a matter of great importance. The following introduces Dingchuang Optical Laser to share with you. The selection of protective lenses for laser cutting machines has the following three principles:: Shape size matching, this is easy to understand;: Material, according to different laser powers, considering the cost of use, it is in the actual application process , Professional manufacturers divide these two types of materials into multiple grades, and customers can choose the corresponding specifications according to actual needs. : Coating, laser anti-reflection coating, different coating technical parameters are adopted according to the use environment. Although the protective lens of the laser cutting machine is a vulnerable part, in order to improve its utilization rate and reduce production costs, the protective lens can be cleaned regularly to achieve the purpose of reuse;

FAQ of Laser Optical Lens

1.When ship?

We could ship the item out to you at once after i get your payment if it in our stock.

2.Are you a manufacture?

Yes, we are factory directly supply.

3.What's your advantages?

Factory dirtectly supply, competitive price, and quality assurance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!