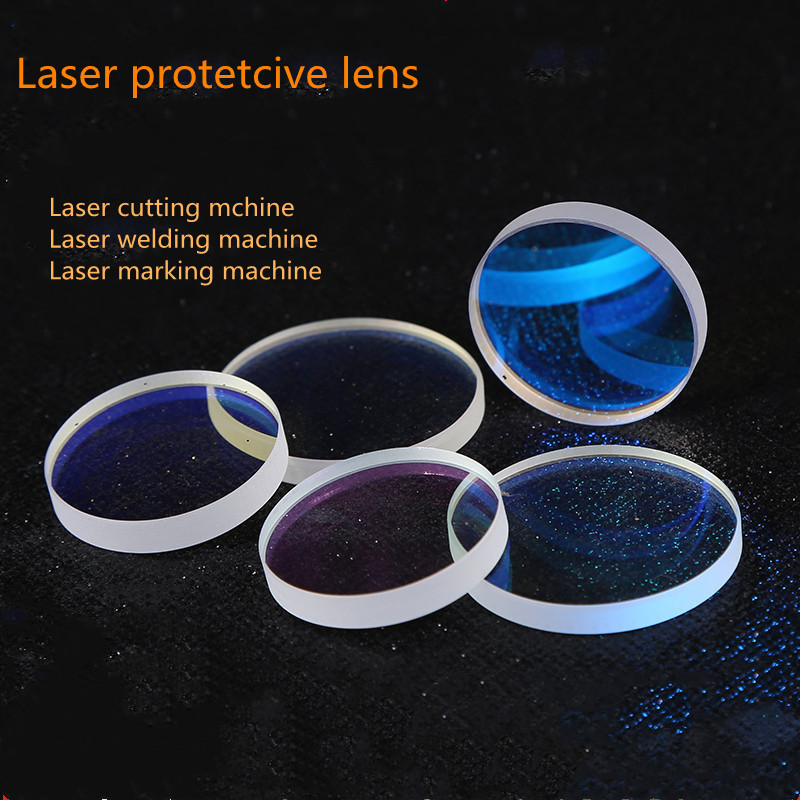

160*8mm Quartz Laser Optical Lens 1064nmAR laser protectiev lenses laser machine

Description:

Laser protection lens is a kind of protective lens of optical laser lens. The main function of laser protection lens is to prevent debris splashing and prevent splashing from damaging the lens. High damage threshold antireflection coatings were coated on both sides to reduce reflection. We try our best to provide all customers around the world with the most valuable products and the best service. At the same time, we can customize all kinds of protective lenses. Widely used in: domestic and foreign brands - such as Han's, Everbright, star, laser Valley, United win, Dineng, Tongfa, Aohua, truking and other laser welding equipment, cutting equipment.

Laser protective lens is an optical glass plate which is polished to form two parallel surfaces. They can be used as protection elements in a variety of complex environments, and their high efficiency of transmittance makes them have little influence on the visible light passing through. The common coating is anti reflection film (AR) and scratch proof film (as), which can also improve the effect according to the needs of customers. It can be waterproof, dust-proof and scratch proof, and can be customized according to the requirements of customers. Optical window is the front protection piece of optical system, which can be used for the packaging of ccd/cmos chip, the protection of optical instruments, measuring instruments and digital equipment, various laser equipment, cover plates on laser diodes, etc.

The basic principle of laser protection lens detection

The impurities in the laser protection lens must be different from those in the optical window. When light is incident to the optical window, the reflection and refraction of various impurities are different from those around the optical window. For example, when the uniform light is perpendicular to the optical window, for example, there is no impurity in the optical window, the direction of emission will not change, and the detected light is even; When there is impurity in the optical window, the emitted light will change the detected image accordingly. Due to the presence of impurities, stress concentration and deformation occur around them, and it is easy to observe in the image. If light transmission defects (such as cracks, bubbles, etc.) are encountered, the light will be refracted at the defect and the intensity of light is greater than that around, so the light detected on the camera target will be enhanced accordingly; If there is any impurity in the light absorbing type (such as sand), the light position at the defect will be weakened, and the light detected on the camera target will be weaker than the surrounding. Through analyzing the intensity and characteristics of the image signal collected by the camera, the corresponding defect information is obtained.

Parameter

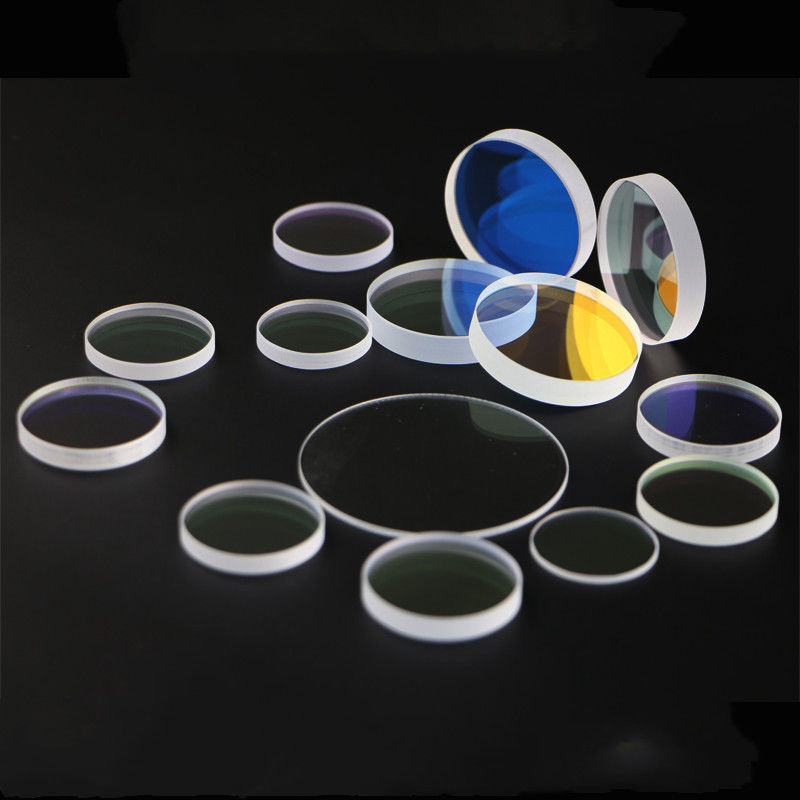

Size:160*8mm

Material:Imported Quartz JGS1

Surface quality:40/20

Clear Aperture:<80%

Transmittance:99.9%

Parallelism:<1 min

Diameter tolearance:+0/-0.1mm

Thickness tolearance:±0.1mm

Advantage:

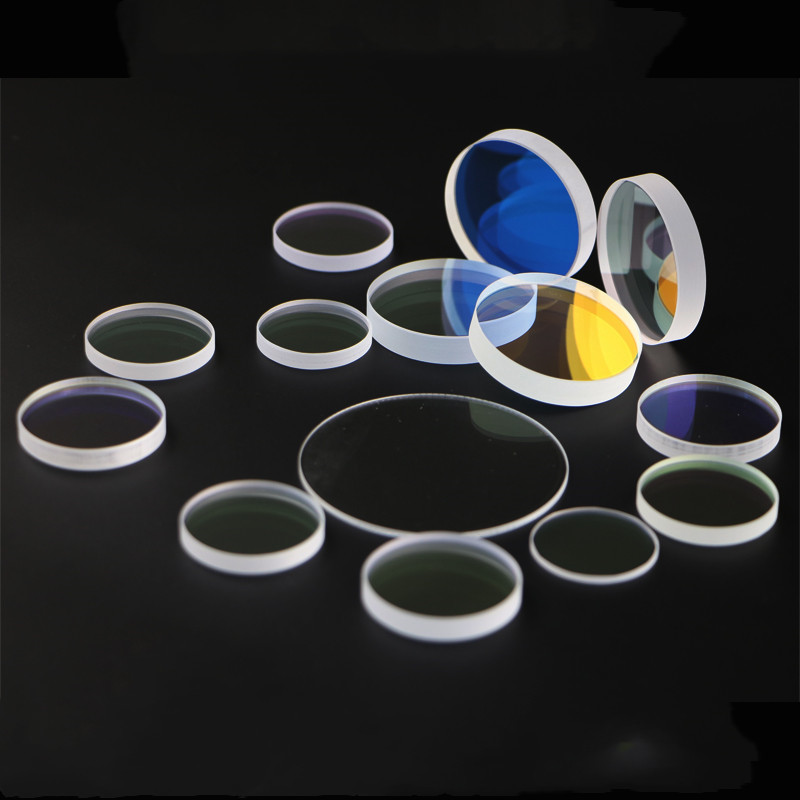

1. Complete standards → our company's protective lenses are complex in variety and sufficient in stock to meet the needs of our customers; It has the characteristics of high anti damage threshold, low residual reflection, low scattering and low absorption.

2. Processing coating → selecting excellent substrate, slicing, rounding, polishing, polishing and coating to make products; The lens is coated with high antireflection film on both sides, which is stable and durable.

3. Other standard maintenance lenses are all inclusive, and the variety is complex. Welcome to consult!

4. The primary function of YAG laser protection lens is to protect the focusing lens, prevent the spatter from sputtering on the lens and causing damage to the lens, and ensure the processing accuracy through regular replacement and maintenance of the lens. The 1064nm antireflection coating with high damage threshold (> 15J / cm2) on the lens can effectively increase the laser transmittance, reduce the energy loss and improve the quality of processed products. Widely used in: laser welding machine, laser cutting machine, laser marking machine and other laser equipment.

For the laser maintenance lens device, the first step is to check the appearance of the laser maintenance lens and its smoothness. When installing the laser maintenance lens, the finger mother should hold the edge of the lens. When installing the lens, do not touch the surface of the maintenance lens. Make sure that the lens installed in the laser cutting head is clean, which is the longest use, Otherwise, dirty spots on the surface of laser maintenance lenses will burn off. Short service life.

Photo:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!