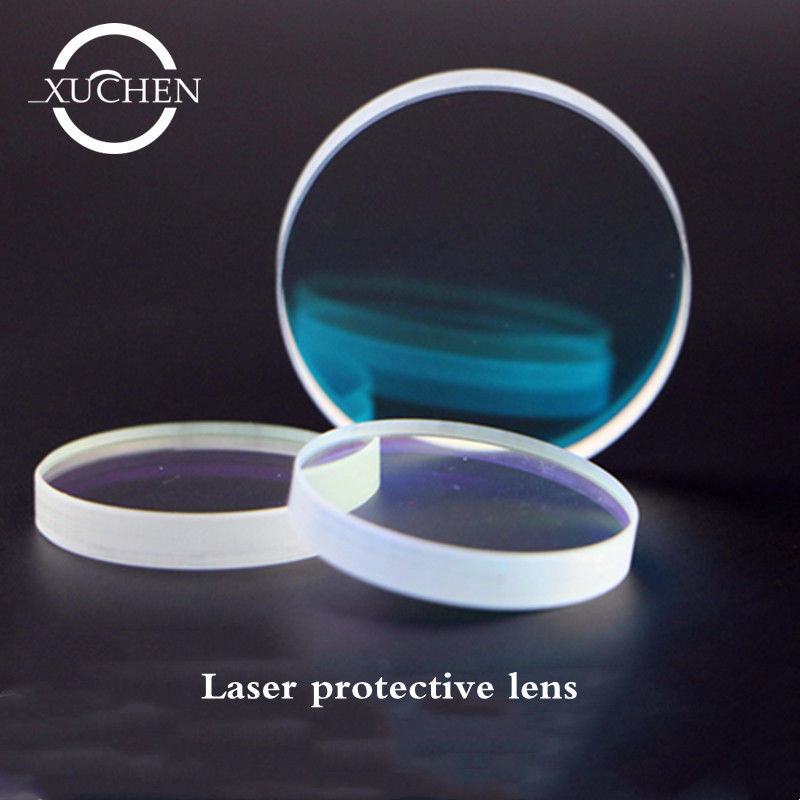

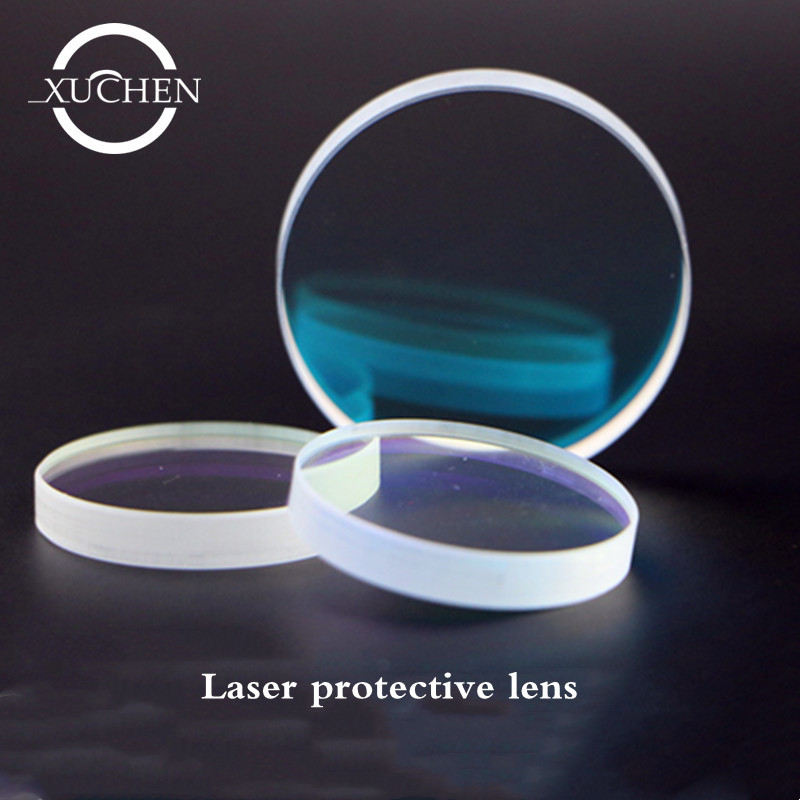

1064nmAR optical glass Window protective Laser Optical Lens Quartz for laser machine

Description :

Laser windows protective lens can provide high transmittance for certain wavelengths of light, which can be used in laser applications and meet the safety requirements. Laser windows can be used for laser transmission and laser safety applications.

The laser window for safe application is designed to provide a safe and observable surface for observing a laser or laser system.

The laser window can also be used to isolate the laser beam, reflect or absorb all other wavelengths. We offer different types of laser window panels for laser transmission and laser blocking applications.

Features:

Size:102*4mm

Material:Imported Quartz JGS1

Surface quality:40/20

Clear Aperture:<80%

Transmittance:99.9%

Parallelism:<1 min

Diameter tolearance:+0/-0.1mm

Thickness tolearance:±0.1mm

Advantages:

1. Complete standards → our company's laser protective lens are complex in variety and sufficient in stock to meet the needs of our customers; It has the characteristics of high Anti-damage threshold,Low residual reflection, Low scattering and Low absorption.

2. Processing coating → selecting excellent substrate, slicing, rounding, polishing, polishing and coating to make products; The protective lens is coated with high Antireflection film on both sides, which is stable and durable.

3. Other standard maintenance lens are all inclusive, and the variety is complex. Welcome to consult!

4. The primary function of YAG laser protection lens is to protect the focusing lens, prevent the spatter from sputtering on the lens and causing damage to the lens, and ensure the processing accuracy through regular replacement and maintenance of the lens. The 1064nm antireflection coating with high damage threshold (> 15J / cm2) on the lens can effectively increase the laser transmittance, reduce the energy loss and improve the quality of processed products. Widely used in: laser welding machine, laser cutting machine, laser marking machine and other laser equipment.

Photos:

How to clean the lens?

1. Flexible cleaning for slightly polluted lenses (dust, fiber particles)

Blow off the scattered pollutants on the lens surface with a blow air bag or cleaning gas. If this step does not remove the contamination, continue with step 2.

Note: avoid using air pipes in the workshop as they usually contain a lot of oil and water. These pollutants will form harmful absorption layer on the surface of lens.

2. Soak a unused special cotton swab with cleaning agent such as acetone or anhydrous alcohol, wipe the lens surface (do not rub hard), slowly drag the wet cotton on the surface of the lens, so that the liquid left behind the wet cotton can evaporate immediately. This will not leave any trace. If this step does not remove pollutants, continue with step 3.

Note: only use pure paper stick swab (Q-tip brand swab is recommended), or polyester fiber swab. It is recommended to use reagent grade acetone, anhydrous ethanol and other cleaners).

3. Soak an unused cotton swab with 6% distilled white vinegar, wipe the lens surface with slight pressure, wipe off the excess distilled vinegar with a clean dry cotton swab, and then soak a cotton swab with acetone to gently wipe the lens surface to remove all acetic acid. If this step does not remove contaminants, continue with step 4.

4. Strong cleaning of severely contaminated (spatter) lenses

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!